March 18, 2025

New OhmBox measures electrical contact resistance during the fastening process

By Randy Bloom

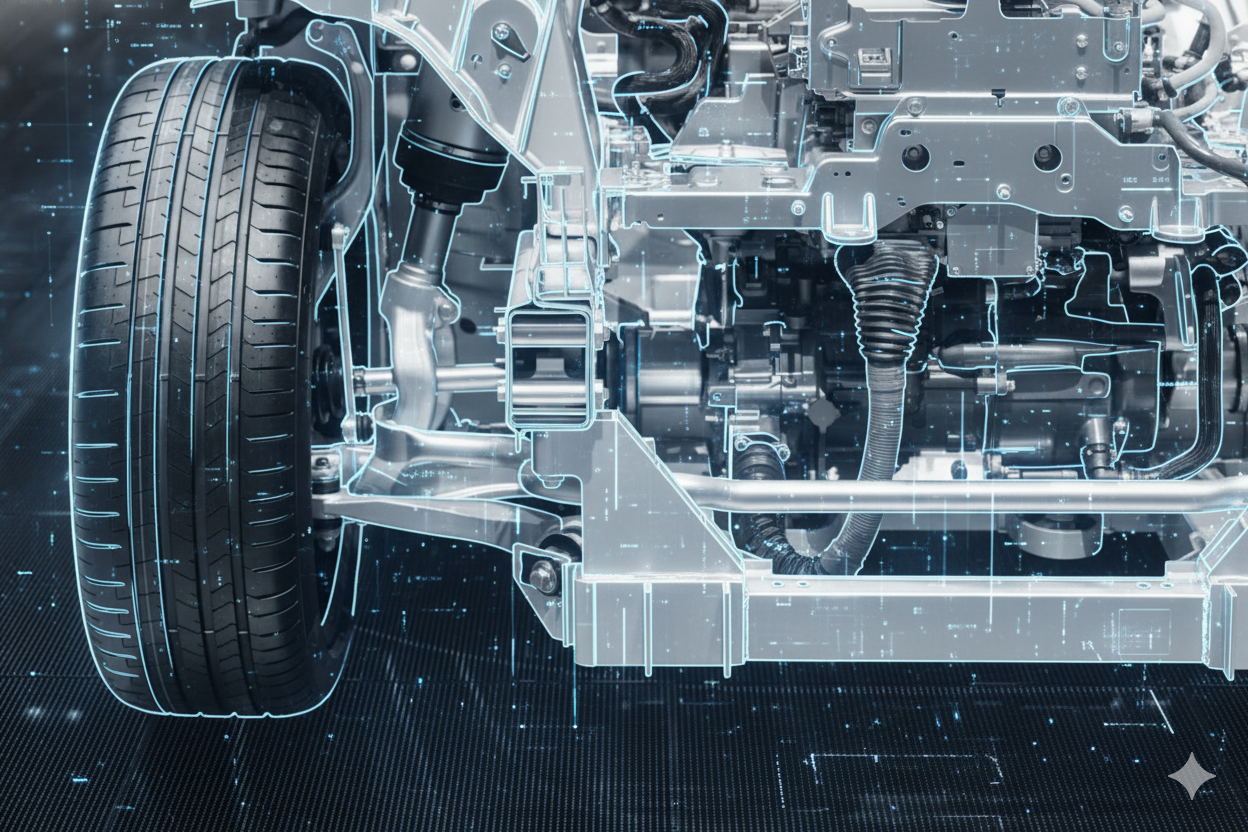

The electrical contact resistance between two fastener components is a key quality parameter, especially when the bolted joints carry electrical current. If the resistance is too high, heat is generated between the elements. In vehicles, for example, this can lead to malfunctions or even trigger fires. In response to this problem, Kistler is adding the OhmBox to its tried-and-tested ANALYSE friction coefficient test stand. Users of the new OhmBox can measure electrical resistance while fastening is actually in progress. This enables developers to define optimal tightening parameters – so they can design safe and reliable current-carrying bolted joints.

Bolted joints have to withstand a lot: they are often subjected to large forces, and they frequently carry electrical current – especially in electric vehicles. Increasing numbers of current-carrying joints are also generating more and more interest in electrical contact resistance as a quality parameter. An optimal bolted joint is the only way to prevent heat generation and damage to surrounding components – and, ultimately, to avoid exposing passengers to danger. Vehicle developers also benefit: a precise analysis of tightening behavior enables R&D departments to determine optimal parameters for bolts and fastener components made of different materials such as copper or aluminum; they can then pass this information on to their customers and sales partners.

OhmBox measures contact resistance while fastening is in progress

To meet this need, Kistler is expanding ANALYSE, its modular friction coefficient test system. With the help of the Kelvin method, users of the new OhmBox can precisely record the electrical contact resistance during the fastening process and correlate it with other parameters such as the applied torque.

To do this, the user connects two measurement tips as close as possible to the bolted joint. The OhmBox then constantly emits current, and the highly sensitive measuring system registers the voltage loss through the electrical contact resistance – even down to the microohm range. In this way, the user can accurately determine the level of electrical resistance during tightening and slackening. To prevent distortion of measured values by external influences, the bolted joint under test can be fully isolated in the test setup.

Evaluation software delivers optimal quality parameters

The testXpert® software records the entire testing procedure, with online user-defined data visualization. In the software, the electrical contact resistance can then be displayed together with other measured values such as the applied torque over the angle or time axis. This allows developers to determine and verify the optimum combination of parameters quickly and reliably – giving them a valid basis for meeting quality requirements and comparing different materials.

The OhmBox can supplement an ANALYSE system that is already in operation, or can be combined with a new ANALYSE system and additional, individually selectable modules for friction coefficient, tightening torque or preloading force. Following a straightforward set-up procedure carried out by Kistler experts, manufacturers can then design and implement a diverse range of test scenarios – thus ensuring that their bolted joints remain safe and reliable, even when carrying electrical current.

Featured Articles

View All

Protecting Critical Infrastructure – Trans Bay Cable Seismic Monitoring

W5 Engineering delivered a turnkey seismic monitoring solution for Trans Bay Cable in the SF Bay Area, installing 11 MEMS sensors, wireless data systems, and DEWESoft integration for critical infrastructure protection.

Identifying Vibration Sources in Foundry Operations

Foundries present a unique challenge when it comes to industrial vibration monitoring. This detailed case study explains the methodology used to pinpoint the exact source of excessive ground vibrations affecting a local residential area. Discover how engineers used multichannel vibration analysis and FFT (Fast Fourier Transform) techniques in DewesoftX software to differentiate between multiple vibrating machines. The key finding was the identification of a complex beating effect caused by the superposition of two units operating at close frequencies, demonstrating the necessity of high-precision condition monitoring to resolve complex noise and vibration problems.

e-NVH Testing: Combining Electric Power and NVH Analysis

The rise of electric vehicles presents unique challenges in acoustics. Dive into the definitive guide on e-NVH testing—the combined analysis of electric drive power, noise, and vibration. This article explains the core principles, common challenges, and a unified multiphysics workflow to bridge the gap between simulation and real-world results. Discover how integrated DAQ solutions and advanced techniques like Order Tracking can accelerate your development cycle and achieve a "first-time-right" electric motor design.