March 18, 2025

How Torrent Washers™ Deliver Superior Results with Less Waste

By Randy Bloom

Spray washers typically use flat spray pattern (V-Jet) nozzles to maximize impingement in the cleaning stage. V- Jet nozzles are available in various flow rates and spray angles at a given nozzle pressure.

In a conventional washer, fixed nozzles are arrayed on spray risers parallel to the vertical axis of the part. Vertical nozzle spacing is determined by the nozzle angle and spaced in a manner to provide full spray coverage over the height of the part. The solution sprayed from a V-Jet nozzle has a “cleaning radius” which is 1.68 times the effective outlet diameter of the nozzle (De). Soils and debris located at a distance greater than 1.68De from the center of the nozzle fan pattern are generally considered irremovable by a specific nozzle.

The fixed nozzle design relies on the conveyor of a continuous moving system to provide relative motion between the nozzles and the part, thereby providing repeated and consistent impingement of the solution on the surface of the part as it passes in front of successive spray risers and nozzles.

Spray riser spacing is typically a function of conveyor speed. The number of risers is determined by the conveyor speed and the required dwell time in a particular process stage. The spray volume (pump capacity) for any particular stage is simply determined:

Pump Capacity (GPM) = No. of Risers x No. of Nozzles per Riser x GPM per nozzle

In order to get full coverage on the vertical axis of the part (nozzles per riser) and the required dwell time (number of risers), the pump sizes for conventional washers can get quite large.

Featured Articles

View All

Protecting Critical Infrastructure – Trans Bay Cable Seismic Monitoring

W5 Engineering delivered a turnkey seismic monitoring solution for Trans Bay Cable in the SF Bay Area, installing 11 MEMS sensors, wireless data systems, and DEWESoft integration for critical infrastructure protection.

Identifying Vibration Sources in Foundry Operations

Foundries present a unique challenge when it comes to industrial vibration monitoring. This detailed case study explains the methodology used to pinpoint the exact source of excessive ground vibrations affecting a local residential area. Discover how engineers used multichannel vibration analysis and FFT (Fast Fourier Transform) techniques in DewesoftX software to differentiate between multiple vibrating machines. The key finding was the identification of a complex beating effect caused by the superposition of two units operating at close frequencies, demonstrating the necessity of high-precision condition monitoring to resolve complex noise and vibration problems.

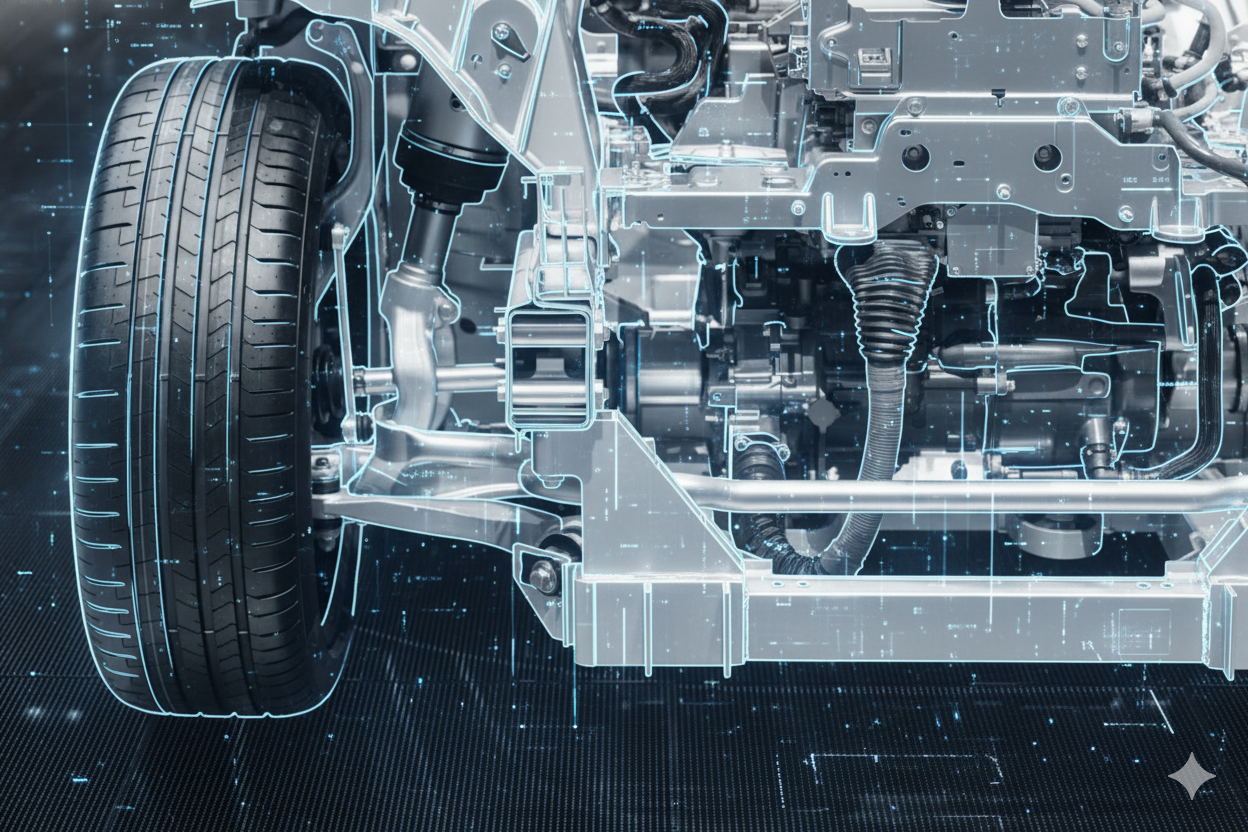

e-NVH Testing: Combining Electric Power and NVH Analysis

The rise of electric vehicles presents unique challenges in acoustics. Dive into the definitive guide on e-NVH testing—the combined analysis of electric drive power, noise, and vibration. This article explains the core principles, common challenges, and a unified multiphysics workflow to bridge the gap between simulation and real-world results. Discover how integrated DAQ solutions and advanced techniques like Order Tracking can accelerate your development cycle and achieve a "first-time-right" electric motor design.