January 07, 2026

How do force sensors and force transducers differ from one another?

By Randy Bloom

Force sensors or force transducers are measurement elements designed for the precise measurement of compression and tensile forces.

Piezoelectric force sensors are based on the piezoelectric measurement principle. They are suitable for measuring (highly) dynamic and quasistatic forces. The force acting on the quartz built into the sensor generates a proportional charge at the signal output. A downstream charge amplifier converts this into a process signal that can be evaluated. One of the special advantages of the piezoelectric measurement element is its constant measurement accuracy over a wide measuring range: thus, it is possible to use a very large sensor to measure the smallest of forces – with constant measurement accuracy. Piezoelectric sensors are also characterized by a high level of overload protection, eliminating the need for protective measures, especially in low measuring ranges.

Force transducers, on the other hand, are sensors that are based on the strain gauge principle. They are suitable for the measurement of static and quasistatic tensile and compression forces. Force transducers can also be used for weighing and for determining torques.

All terms are now used universally, which is why it is not possible to establish a clear delineation.

Featured Articles

View All

Protecting Critical Infrastructure – Trans Bay Cable Seismic Monitoring

W5 Engineering delivered a turnkey seismic monitoring solution for Trans Bay Cable in the SF Bay Area, installing 11 MEMS sensors, wireless data systems, and DEWESoft integration for critical infrastructure protection.

Identifying Vibration Sources in Foundry Operations

Foundries present a unique challenge when it comes to industrial vibration monitoring. This detailed case study explains the methodology used to pinpoint the exact source of excessive ground vibrations affecting a local residential area. Discover how engineers used multichannel vibration analysis and FFT (Fast Fourier Transform) techniques in DewesoftX software to differentiate between multiple vibrating machines. The key finding was the identification of a complex beating effect caused by the superposition of two units operating at close frequencies, demonstrating the necessity of high-precision condition monitoring to resolve complex noise and vibration problems.

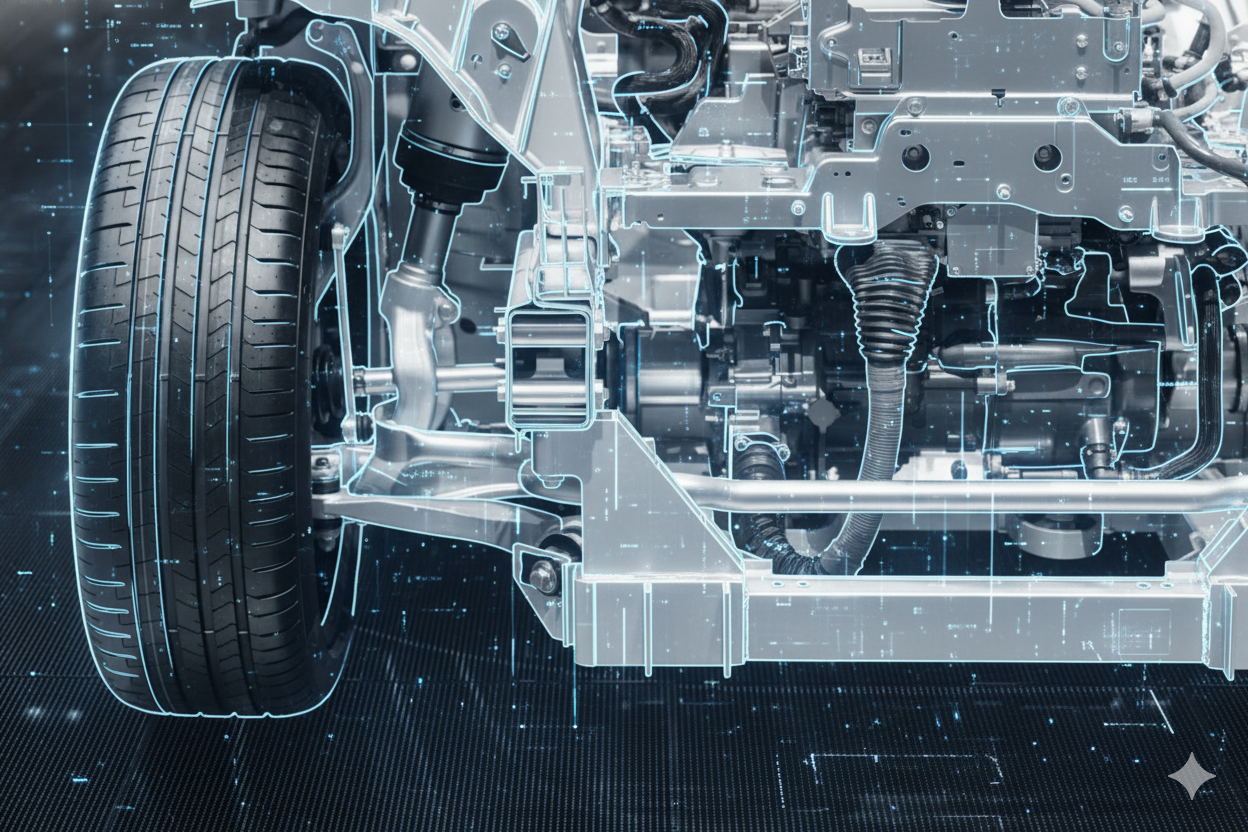

e-NVH Testing: Combining Electric Power and NVH Analysis

The rise of electric vehicles presents unique challenges in acoustics. Dive into the definitive guide on e-NVH testing—the combined analysis of electric drive power, noise, and vibration. This article explains the core principles, common challenges, and a unified multiphysics workflow to bridge the gap between simulation and real-world results. Discover how integrated DAQ solutions and advanced techniques like Order Tracking can accelerate your development cycle and achieve a "first-time-right" electric motor design.