June 25, 2025

How Do Test Chambers Get So Cold?

By Randy Bloom

What are the limitations of environmental chambers in achieving LOW temperatures

When we hear from folks searching for a test chamber for the first time, they are sometimes surprised that we can get temperatures down to -94° Fahrenheit (-70° Celsius). To help you understand the different methods of cooling a chamber and how cold they can go, take a look below: It’s a quick review of each plateau of limitation in cooling a test chamber, from room temperature, to as low as -170°C.

20°C above ambient

This lower limit is common for chambers that don’t have any refrigeration. Because there is heat generated by the fan recirculating the air, we cannot guarantee temperatures close to the room ambient. So even if you just want a stable “ambient” temperature, you will need refrigeration. This low temperature is usually specified for ovens.

5 to -20°C

This is about as low as we can go with a standard refrigeration using R-134A refrigerant. This is the same refrigerant that is currently used in new air conditioning systems and refrigerators. This refrigerant is not widely used in the test chamber industry due to its limited range. To learn more about refrigeration, see this webpage.

-35 to –40°C

This is the lowest range that chambers can achieve with R-404A or R-507 refrigerants. The type of refrigeration system they use is called “single stage”, which basically means that there is one compressor. Chambers with this range are often only used to –20 or –25°C when cycling temperatures between hot and cold. Going to lower temperatures becomes a slow process. Higher performance systems may even limit the lower temperature more strictly in order to maximize the system to meet a desired test range in a specified time.

-65 to –73°C

Chambers that can get this low use “cascade” refrigeration. By using a “high stage” refrigeration circuit to cool the “low stage” circuit, these cold temperatures can be achieved. The low stage refrigerants (R-23 or R-508) would create too much pressure (which would blow-out the piping) if they were used alone, which is why the high stage is added. The high stage ensures the low stage doesnt’ reach too high a pressure by cooling it.

Cascade cooling is less efficient ... even though there are two compressors, you really only have the cooling power of one. Plus, there are losses due to inefficiencies of heat transfer between the stages.

-85 to -150°C

To get this cold, a triple cascade refrigeration system is used. This is rare in test chambers, although it is common for ultra-cool freezers.

-170°C

Chambers that can get this low use liquid nitrogen for cooling. Nitrogen is a cheap method for cooling a chamber, however long term use of liquid nitrogen can get expensive. It is best suited for:

- Small or infrequently used chambers

- Chambers that especially need this low range

- Chambers that need temperature change rates greater than 30°C/m.

Featured Articles

View All

Protecting Critical Infrastructure – Trans Bay Cable Seismic Monitoring

W5 Engineering delivered a turnkey seismic monitoring solution for Trans Bay Cable in the SF Bay Area, installing 11 MEMS sensors, wireless data systems, and DEWESoft integration for critical infrastructure protection.

Identifying Vibration Sources in Foundry Operations

Foundries present a unique challenge when it comes to industrial vibration monitoring. This detailed case study explains the methodology used to pinpoint the exact source of excessive ground vibrations affecting a local residential area. Discover how engineers used multichannel vibration analysis and FFT (Fast Fourier Transform) techniques in DewesoftX software to differentiate between multiple vibrating machines. The key finding was the identification of a complex beating effect caused by the superposition of two units operating at close frequencies, demonstrating the necessity of high-precision condition monitoring to resolve complex noise and vibration problems.

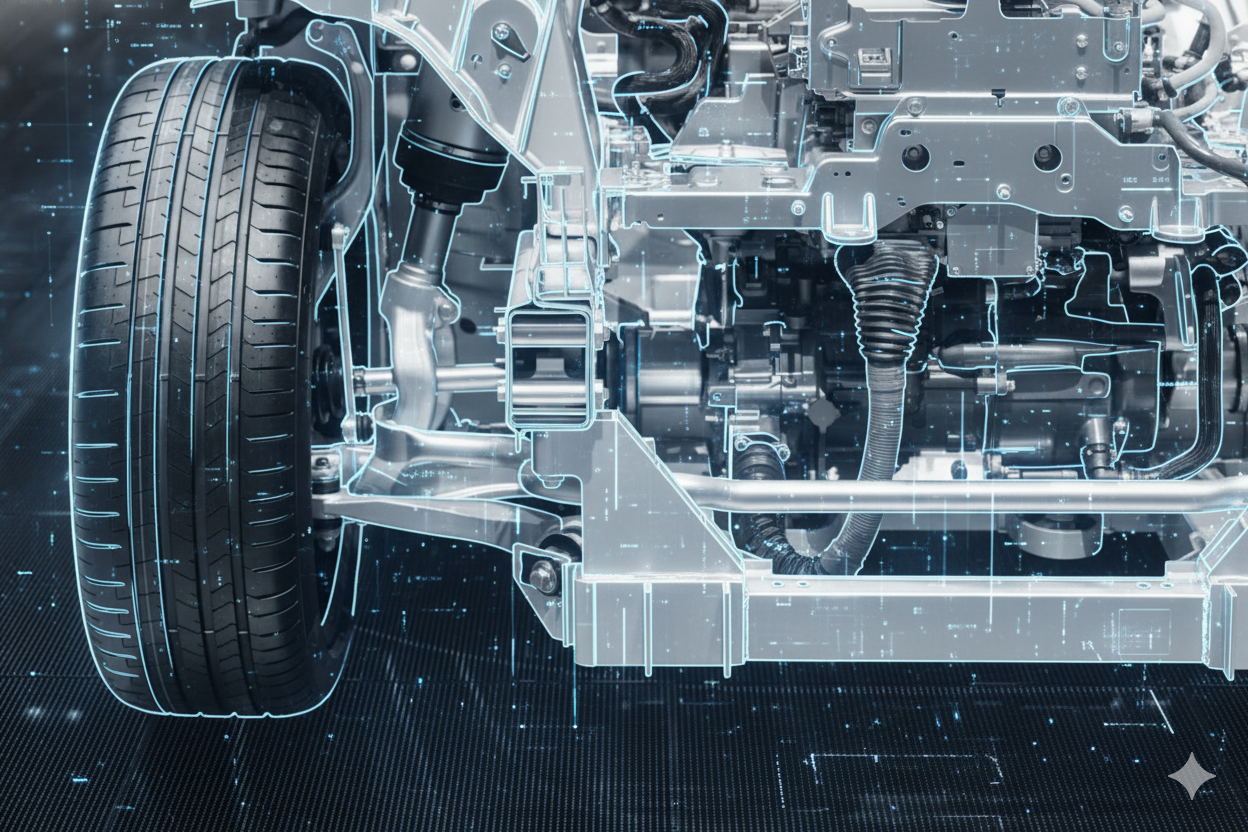

e-NVH Testing: Combining Electric Power and NVH Analysis

The rise of electric vehicles presents unique challenges in acoustics. Dive into the definitive guide on e-NVH testing—the combined analysis of electric drive power, noise, and vibration. This article explains the core principles, common challenges, and a unified multiphysics workflow to bridge the gap between simulation and real-world results. Discover how integrated DAQ solutions and advanced techniques like Order Tracking can accelerate your development cycle and achieve a "first-time-right" electric motor design.