April 11, 2025

Seismic Monitoring: W5's Full-Service Approach

By Tony DePaolantonio

With the new assembly workstation for pressing and joining Smart Single Station (SST) 2nd Generation, Kistler presents a fully optimized version of the proven servo press workstation for automated assembly and testing processes. The system can either be used as a manual workstation or fully integrated into the production line. The new version is significantly easier to operate, allowing inexperienced employees to perform various assembly and testing processes correctly. Further improvements including easier data export and the newly designed front door ensure smooth workflows on today’s busy shopfloors.

Whether it’s vehicle components, cables and electronics, white goods, packaging or medical equipment – in modern manufacturing, the latest requirements must be addressed as quickly as possible without compromising cycle time or quality. For maximum flexibility and guaranteed product quality, Kistler offers the Smart Single Station (SST), a customizable assembly workstation for diverse and application-specific pressing and joining tasks as well as test processes. The system can be used as a stand-alone workstation or integrated into a fully or partially automated production line to control, evaluate and document manufacturing processes. The integrated maXYmos NC process monitoring system for force-displacement monitoring enables quality inspection of joining and pressing processes, ensuring their traceability. In addition to flexibility and seamless product quality, even the smallest time savings in operational workflow are crucial. That’s why Kistler has now further optimized the Smart Single Station to better adapt to the various conditions in the often tightly scheduled manufacturing routine.

Assembly workstation for pressing and joining ensures stream-lined workflows

The new SST 2nd Generation can be set up by parameterization; programming knowledge is not necessary. Its operation is now controlled centrally via an integrated screen. Illustrated instructions guide users through the testing or assembly processes, allowing even inexperienced operators to quickly and accurately start using the machine. They can select programs either by scanner or manually. The collected measurements are displayed in real time. A new and particularly powerful feature of the maXYmos NC process monitoring system enables the operator to filter measurement data and then export the selection. This facilitates the subsequent evaluation of the production and analysis data.

To make the Smart Single Station even more user-friendly during everyday tasks, Kistler has revised the mechanics of the second generation. This includes a completely redesigned front door and service door. The front door can now be stopped in any position to improve workflows – making it no longer necessary to fully open it during each cycle. This makes work more ergonomic and saves valuable time. The service door now opens up to 180 degrees, providing easier access to the tool holder. Additionally, the upper frame can be completely removed for maintenance on the NC joining module or sensor calibration.

Efficient and flexible manufacturing with the SST and electromechanical joining systems

Kistler designs its SST assembly workstations to meet individual customer needs and the requirements of the respective joining, assembly and testing tasks. The manual servo press workstations are equipped with Kistler's electromechanical NC joining modules and are designed for various joining processes, including pressing, clinching, caulking, riveting and punching, as well as for thermo-bonding and testing springs. Thanks to their energy efficiency, electromechanical joining systems improve the CO2 balance and make a valuable contribution to climate protection. In addition to joining and pressing processes, other industry-specific manufacturing processes can be implemented with the Smart Single Station. The SST can for instance be equipped with high-resolution cameras for special optical inspections to realize 100 percent quality assurance.

As a trusted distributor of Kistler solutions, W5 Engineering is committed to providing innovative and efficient manufacturing technologies tailored to your needs. Whether you're looking to integrate the Smart Single Station (SST) 2nd Generation into your production line or need expert consultation on optimizing your assembly and testing processes, our team is here to help. Contact W5 Engineering today to explore how we can support your automation goals with Kistler’s advanced solutions.

Featured Articles

View All

Protecting Critical Infrastructure – Trans Bay Cable Seismic Monitoring

W5 Engineering delivered a turnkey seismic monitoring solution for Trans Bay Cable in the SF Bay Area, installing 11 MEMS sensors, wireless data systems, and DEWESoft integration for critical infrastructure protection.

Identifying Vibration Sources in Foundry Operations

Foundries present a unique challenge when it comes to industrial vibration monitoring. This detailed case study explains the methodology used to pinpoint the exact source of excessive ground vibrations affecting a local residential area. Discover how engineers used multichannel vibration analysis and FFT (Fast Fourier Transform) techniques in DewesoftX software to differentiate between multiple vibrating machines. The key finding was the identification of a complex beating effect caused by the superposition of two units operating at close frequencies, demonstrating the necessity of high-precision condition monitoring to resolve complex noise and vibration problems.

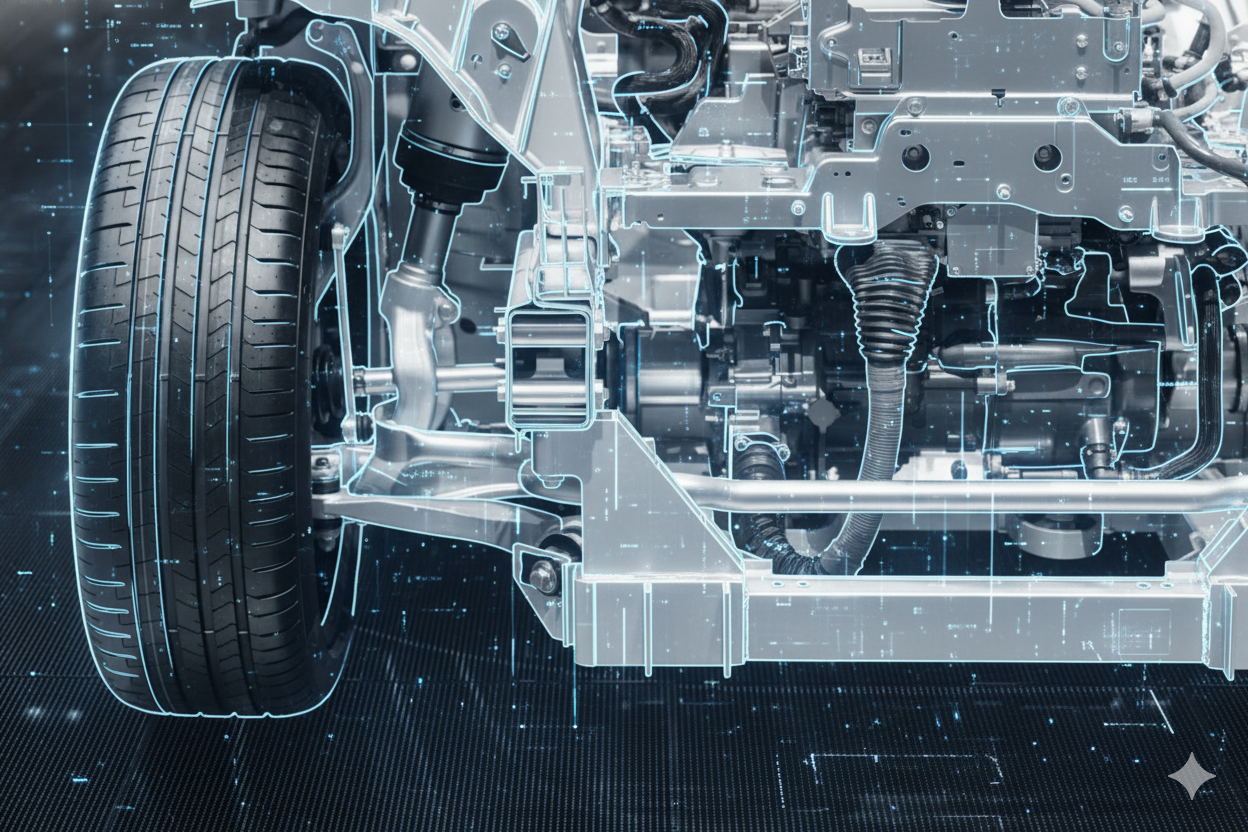

e-NVH Testing: Combining Electric Power and NVH Analysis

The rise of electric vehicles presents unique challenges in acoustics. Dive into the definitive guide on e-NVH testing—the combined analysis of electric drive power, noise, and vibration. This article explains the core principles, common challenges, and a unified multiphysics workflow to bridge the gap between simulation and real-world results. Discover how integrated DAQ solutions and advanced techniques like Order Tracking can accelerate your development cycle and achieve a "first-time-right" electric motor design.