Redefine Battery Testing with the BTS 10300 Series

The EA-BTS 10300 Series Battery Cycler & Test System is engineered to meet the rigorous demands of modern battery and energy storage testing. Featuring voltage ranges up to 1500 VDC (optional 2000 VDC), current capacities up to 30,720 A, and power scalability up to 3.84 MW, it delivers unparalleled performance for applications ranging from EV battery packs to industrial grid storage.

This advanced system integrates 96.5% energy regeneration efficiency, true autoranging for continuous cycling, and modular rack configurations that adapt to your evolving testing requirements. Its widget-based software interface eliminates the need for coding, allowing users to program tests and analyze data effortlessly. With robust safety features, including temperature monitoring and reverse polarity protection, the BTS 10300 Series ensures precise and reliable results.

Whether you are developing next-generation batteries, optimizing energy systems, or conducting research and development, the EA-BTS 10300 Series provides the tools you need to innovate with confidence.

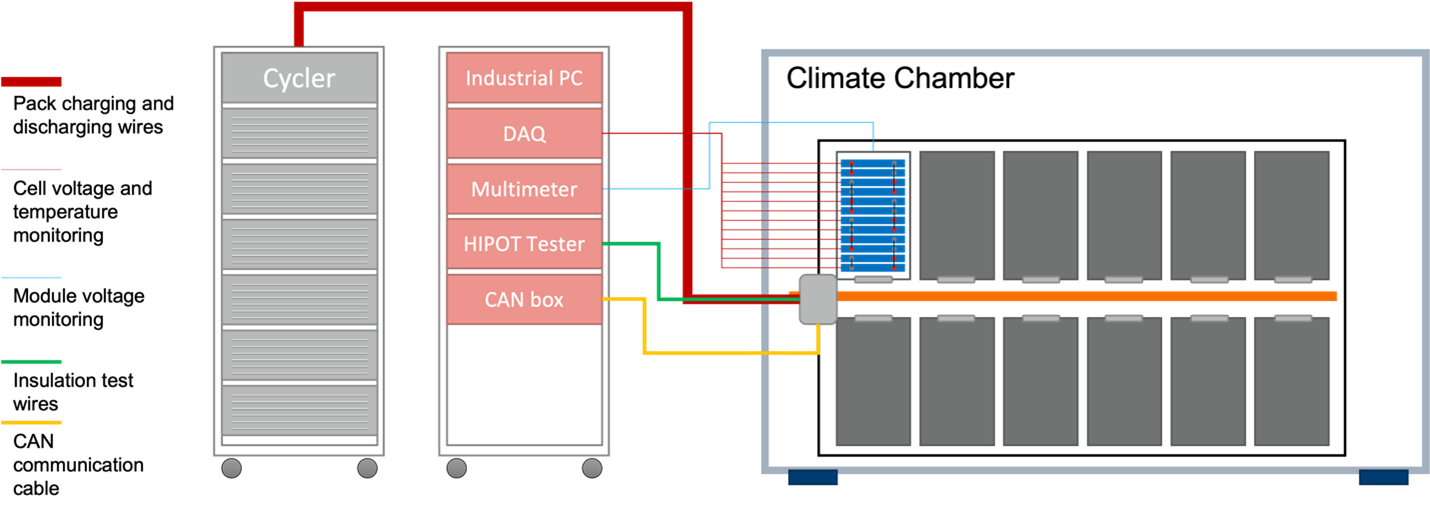

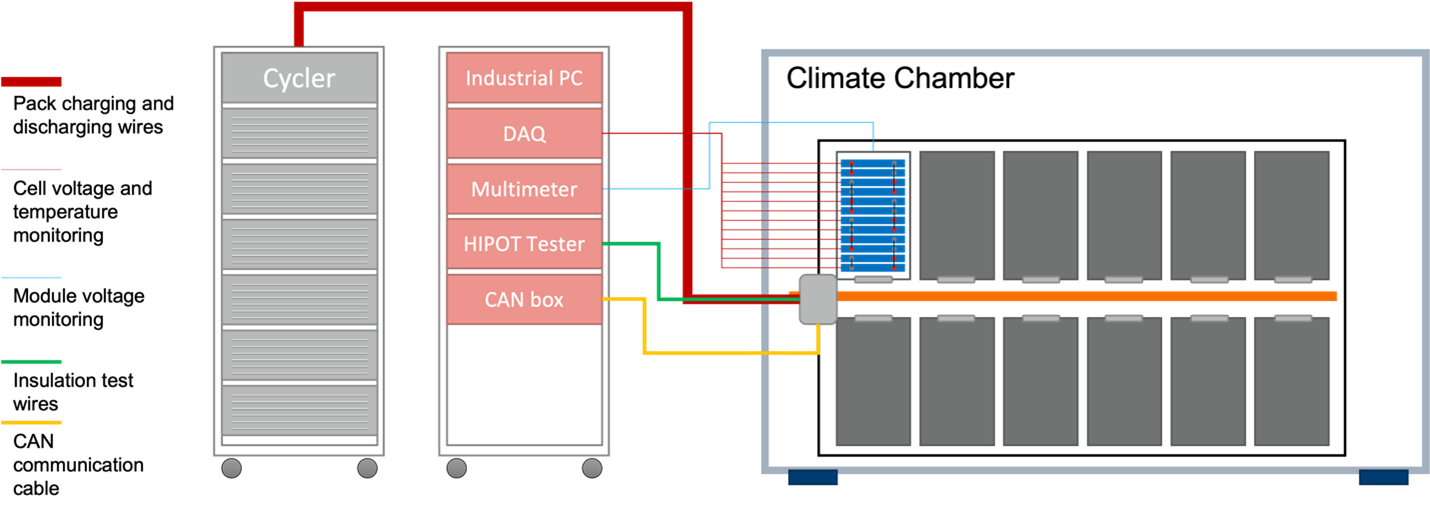

A typical, non EA multi-rack battery pack testing system

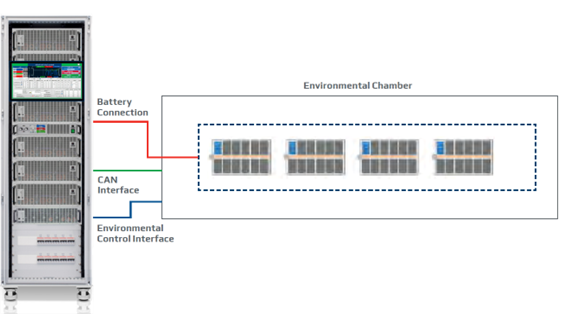

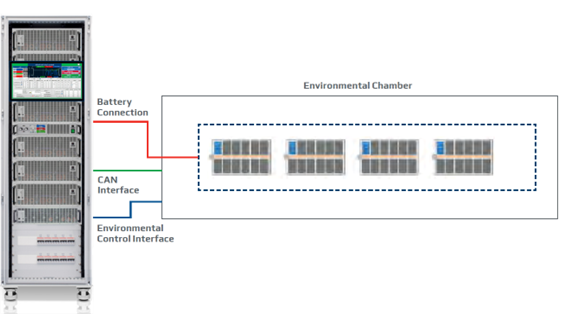

Compared wtih the EA-BTS 10300 System that integrates all of the testing and communications into a single rack

Expandable power capacity from 30-300kW to a maximum of 3.84MW

The EA-BTS 10300 system sets itself apart from conventional test systems with its TRUE autoranging feature. This unique capability allows the programmable power source to deliver the necessary power across a broad spectrum of voltage conditions, offering unparalleled flexibility and efficiency in battery testing.

Specifications

Power Configurations

30 kW, 60 kW, 90 kW, 100 kW, 120 kW, 180 kW, 200 kW, 240 kW, 300 kW

Tests

Can be user-defined such as capacity, four seasons, pulse, and imported drive cycling.

Battery Cycling

- Voltage range: 0–1500 VDC (0–2000 VDC optional)

- Current range: ±30,720 Amps (single cabinet ±2,400 Amps)

- Power range: 0–3.84 MW (single rack up to 300 kW)

Drive Cycle Simulations

FUDS, SFUDS, GSFUDS, DST, and ECE-ISL

Battery Monitoring

- Parameters: voltage, current, power, step, total AH/WH

- Sampling rate: 1.6 kHz

- BMS signals

- Input from battery for limitations from BMS to cycler

Interface to Battery Management System

CAN bus

Chiller and Environmental Chamber Control

Interface to temperature controllers

Configurable User Variables and Alarms/Warnings

Pick and choose logs, what rate to record, and which signals

Supports multiple log foles at once

Safety Features

- Battery pack temperature monitoring:

- Sensor: Thermocouple Type K standard, system can be built with other types

- Temperature range: Depending on thermocouple chosen

- Accuracy: Depending on thermocouple chosen

- Voltage matching accuracy: ≤1% battery voltage

- Polarity reversal check:

- E-Stop

- Configurable emergency shutdown sequence

Software

- Export data format: CSV and TDMS (NI structured binary format; can be read in MATLAB), HDF5

- Widget-based display control

System Input Power Requirements

380 V / 400 V / 480 V ±10%, 3-phase AC (Wide range AC input)

Test System Cooling Requirements

Forced air (Water cooling optional)

Power Delivery and Absorption Performance

96.5% regeneration to the grid

Standard I/O

- 4 Digital outs

- 5 Digital ins

- 4 Analog ins

- 3 Thermocouple inputs (Type K) can be ordered with other types

Optional Features

- Multichannel control

- Chiller control

- Vehicle charging protocol and control

- Custom solutions also available – inquire with your regional sales representative

Resources

Interfaces and Software

EA-BTS battery test software controls all battery cycling and battery test operations and enables:

- Defining the tests to be performed

- Entering parameters for the tests

- Defining the order in which tests are performed

- Defining the data to be monitored and exported

- Defining the layout of the display screen

The Software uses a Widget-based approach to allow a user-configurable display. Set up and test execution is simple and fast and allows complete tests on a battery or another power source, such as a fuel cell.